To calculate the price of your job, take the cost of the type of Spray Foam you choose:

Open-cell Spray Foam cost is generally 0,40 to 0,65 cents per board foot

Closed-cell Spray Foam cost is generally $ 0.95 - $1.20 per board foot

For example,

2,500 sq ft, At 2" thick of closed cell = $4,750. to $6,000

2,500 sq ft, At 4" thick of open cell = $4,000. to $6,500

Minimum Service Charge Per Job is $2.100 To $2.500. Depending on Your Job and Situation.

Staten Island NY - Spray Foam Insulation Contractor

Staten Island NY - Best Spray Foam Insulation Contractor - Insulation Installers in NY - NJ

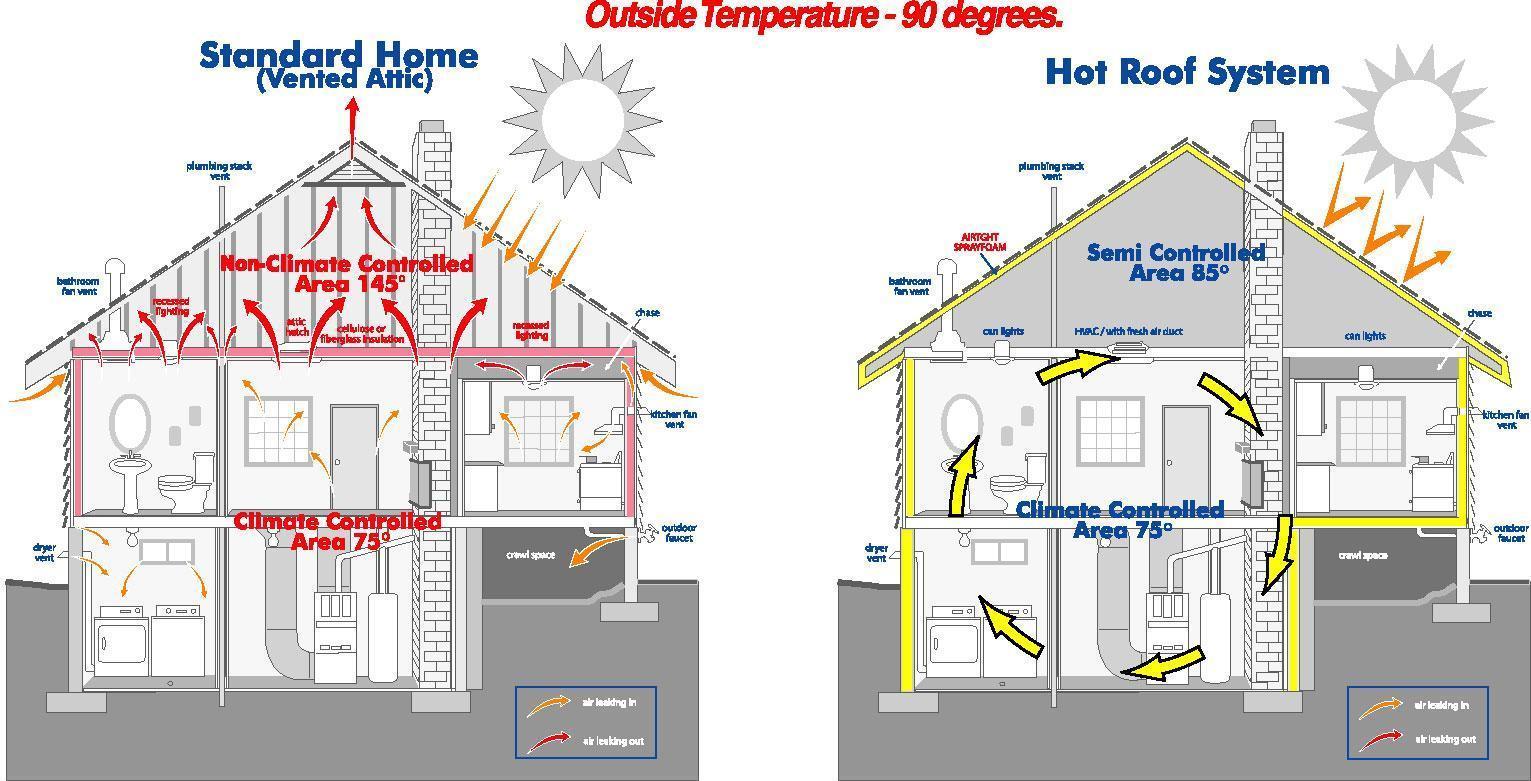

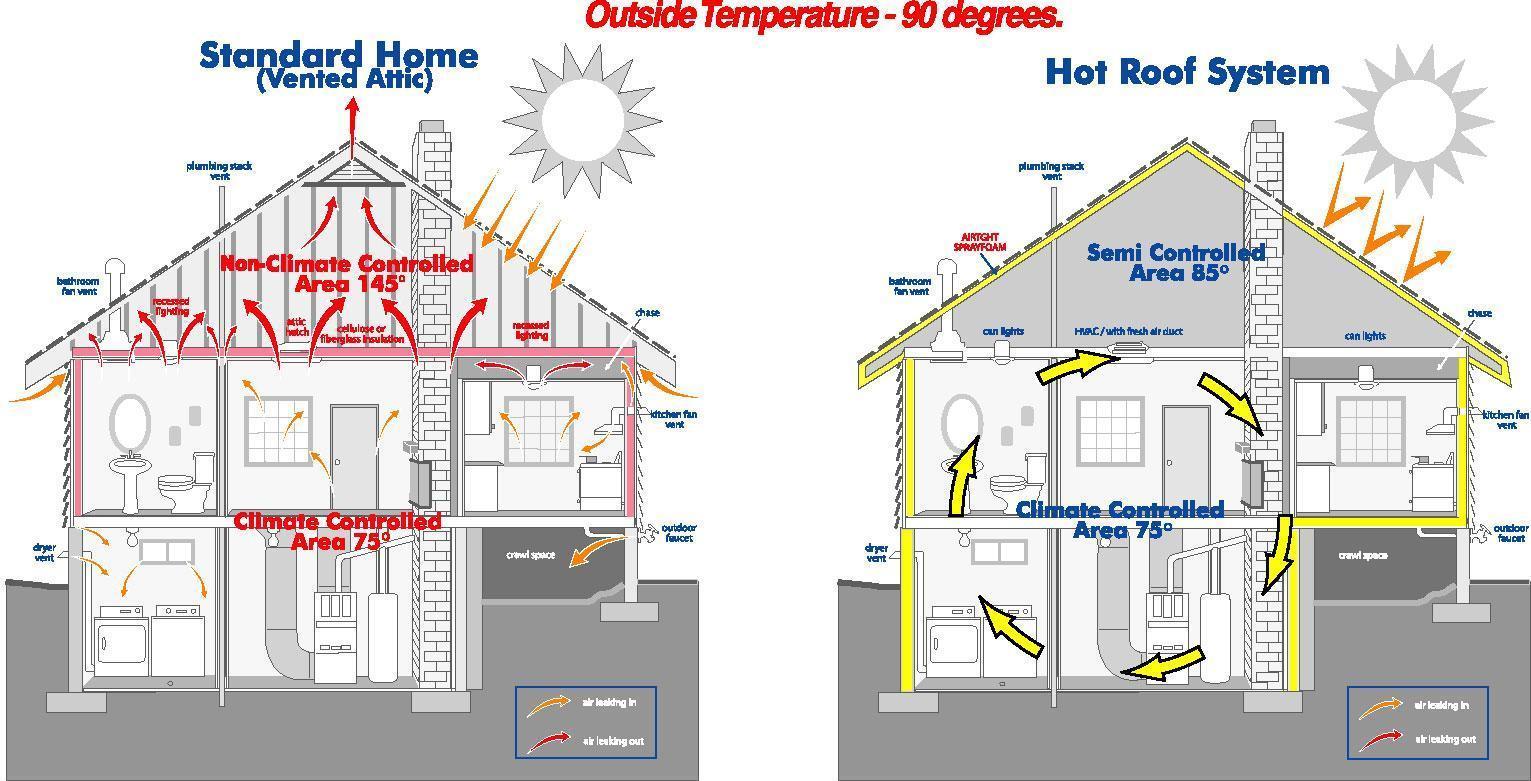

Spray foam insulation can maximize a homeowners investment by sealing the building envelope to stop conditioned indoor air from escaping and prevent unconditioned air from entering a home.

Air exchange in and out of a home is a leading cause of escalated energy bills.

The mechanical systems that heat and cool buildings are continuously operating; reducing extreme temperature variations saves on the overuse of mechanical systems and leads to lower energy bills.

What is Spray Foam Insulation

Spray Foam Insulation is a spray-applied plastic that can form a continuous insulation and air sealing barrier on walls, roofs, around corners, and on all contoured surfaces. It is made by mixing and reacting unique liquid components at the job site to create foam. The liquids react very quickly when mixed, expanding on contact to create foam that insulates, seals gaps, and can form moisture and vapor barriers. Spray Foam Insulation is known to resist heat transfer extremely well, and it offers a highly effective solution in reducing unwanted air infiltration through cracks, seams, and joints.

Closed-cell spray foam exterior applications

- Can reject bulk water (ideal for flood zones)

- Higher R-value* per inch – easier to accommodate high R-value* requirements in narrow spaces

- Adds wall racking strength as well as impact resistance

- Can be applied at very low temperatures (as low as 5oF)

- Ideal for continuous insulation solutions

- Lower vapor permeance (can be a Class II VDR)

- Higher tensile and bond strength

Open-cell spray foam interior applications

- Hydrophobic material

- Permits bi-directional drying

- Can achieve greater R-value* if not restricted by space

- Can be installed at a significantly lower cost and target the same specified R-value*

- Lower raw material/resource use

- Will accommodate long-term creep and seasonal movement

- Air barrier and insulating material

Comparison Chart

|

|

Open-Cell Spray Foam | Closed-Cell Spray Foam |

|---|---|---|

Spray In Insulation and Air Barrier Material |

|

|

Vapor Barrier |

|

|

Vapor Permeability |

|

|

Structural Reinforcement |

|

|

Able to deflect water and reject bulk water |

|

|

Able to accommodate seasonal shifting |

|

|

Cannot sustain mold |

|

|

R-Value (at 1")* |

3.7 | 6 |

Blowing Agent |

Water | Chemical, Water |

Suitability |

Interior | Interior, Exterior |

Sound Dampening |

|

|

Cost |

$ | $$$ |

Licensed Spray Foam Insulation Contractor

Always Use A Licensed Spray Foam Insulation Contractor

The best way to do that is to make sure you hire a licensed spray foam insulation contractor to install your new insulation, such as the licensed contractors who install Icynene spray foam.

Why the emphasis on a contractor who is licensed to work with Spray Foam, specifically? The licensing process that takes place for an Icynene contractor involves comprehensive training and examination. No Icynene insulation contractor can use the product before completing and passing the exam, so you can be confident that a licensed Icynene contractor coming into your home to install Icynene Spray Foam has a comprehensive understanding how to handle both the materials and the equipment being used.

Spray Foam Insulation Contractor Staten Island NY.

Staten Island NY - Best Spray Foam Insulation Contractor - Insulation Installers in NY - NJ

Spray foam insulation can maximize a homeowners investment by sealing the building envelope to stop conditioned indoor air from escaping and prevent unconditioned air from entering a home.

Air exchange in and out of a home is a leading cause of escalated energy bills.

The mechanical systems that heat and cool buildings are continuously operating; reducing extreme temperature variations saves on the overuse of mechanical systems and leads to lower energy bills.

What is Spray Foam Insulation

Spray Foam Insulation is a spray-applied plastic that can form a continuous insulation and air sealing barrier on walls, roofs, around corners, and on all contoured surfaces. It is made by mixing and reacting unique liquid components at the job site to create foam. The liquids react very quickly when mixed, expanding on contact to create foam that insulates, seals gaps, and can form moisture and vapor barriers. Spray Foam Insulation is known to resist heat transfer extremely well, and it offers a highly effective solution in reducing unwanted air infiltration through cracks, seams, and joints.

Closed-cell spray foam exterior applications

- Can reject bulk water (ideal for flood zones)

- Higher R-value* per inch – easier to accommodate high R-value* requirements in narrow spaces

- Adds wall racking strength as well as impact resistance

- Can be applied at very low temperatures (as low as 5oF)

- Ideal for continuous insulation solutions

- Lower vapor permeance (can be a Class II VDR)

- Higher tensile and bond strength

Open-cell spray foam interior applications

- Hydrophobic material

- Permits bi-directional drying

- Can achieve greater R-value* if not restricted by space

- Can be installed at a significantly lower cost and target the same specified R-value*

- Lower raw material/resource use

- Will accommodate long-term creep and seasonal movement

- Air barrier and insulating material

Comparison Chart

|

|

Open-Cell Spray Foam | Closed-Cell Spray Foam |

|---|---|---|

Spray In Insulation and Air Barrier Material |

|

|

Vapor Barrier |

|

|

Vapor Permeability |

|

|

Structural Reinforcement |

|

|

Able to deflect water and reject bulk water |

|

|

Able to accommodate seasonal shifting |

|

|

Cannot sustain mold |

|

|

R-Value (at 1")* |

3.7 | 6 |

Blowing Agent |

Water | Chemical, Water |

Suitability |

Interior | Interior, Exterior |

Sound Dampening |

|

|

Cost |

$ | $$$ |